water vapor permeability test procedure distributor|water vapor permeance explained : Brand Labthink has the most complete product line of water vapor permeability testing instruments in packaging industry worldwide. Water vapor permeability is a measure of the passage of water vapor through a membrane. Há 15 minutos a polícia não tem qualquer contato com as pessoas que estão presas dentro de um edifício em quarentena. Ninguém sabe o que aconteceu lá dentro. Neste .

{plog:ftitle_list}

Publicado por Megapackscp 6 de febrero de 2024 6 de febrero de 2024 Publicado en Cp Caldo de Pollo, Cp por mega, Mega packs cp, Pack cp 2024, Pack cp por mega Etiquetas: 2024 cp pack, caldo de polllo link cp mediafire, Caldo de posho cp, cp caldo de pollo, cp caldo de pollo 2024, cp caldo de pollo download, cp google drive mediafire, Cp Link .

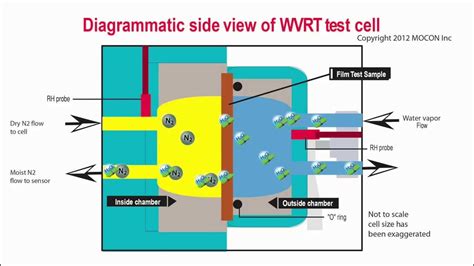

Detailed video explanation of ASTM E96-22 standard desiccant and water test methods for water vapor transmission rate of materials.

Labthink has the most complete product line of water vapor permeability testers in packaging industry worldwide. Water vapor permeability is a measure of the passage of water vapor through a membrane.MOCON provides Water Vapor Permeation Analyzers for testing water vapor & moisture transmission rate of films and packages for many applications. Call us today! The “dry cup” method involves utilizing a desiccant within the test cup and maintaining 50% RH in the ambient chamber. Water vapor is expected to diffuse into the cup (i.e., the cup’s mass will increase over time), and the mass .

Labthink has the most complete product line of water vapor permeability testing instruments in packaging industry worldwide. Water vapor permeability is a measure of the passage of water vapor through a membrane. Understanding how much water vapor can pass through various materials used in wall assemblies is an important factor in selecting an air barrier to meet a specific wall .ASTM D1653 - Standard Test Methods for Water Vapor Transmission of Organic Coating Films. C360M aslo Water Vapor Permeability Tester, is designed and manufactured based on the gravimetric determination method and conforms to .Scope: The test evaluates the water vapor transfer through semi-permeable and permeable samples. The data can be used by manufacturers and designers and is often important in .

water vapor transmission rate Ñthe steady water vapor ßow in unit time through unit area of a body, normal to speciÞc parallel surfaces, under speciÞc conditions of temperature and humidity at each surface.Ó 4. Summary of Test Methods 4.1 In the Desiccant Method the test specimen is sealed to Protocol of water vapor permeability measurement using the cup test method; . We now propose modifying the usual cup test procedure to overcome this difficulty. The modification consists of measuring the total gas pressure in the climatic room and the cup during the test. In this way, the water vapor partial pressure, the total gas pressure . While water vapor generally cannot harm humans, since it is just water in a different state of matter, it can be troublesome for many materials used for different purposes. Determining the water vapor transmission rate (WVTR) .

Cup experiments are the most widely used method to measure the water vapor permeability of porous building materials. For this test, cup assembly is designed to create a vapor pressure gradient across a sample and, thus, to allow vapor diffusion through it. Water vapor permeability is assessed by weighing cup assembly over time.Two general types of permeability test methods are routinely performed in the laboratory: (1) the constant head test method, and (2) the falling head test method. The constant head test method is used for cohesionless and more permeable soils (k>10-4 cm/s) and the falling head test is mainly used for cohesive or less permeable soils (k<10-4 cm .Water vapor permeability is one of the main performance indexes of package materials. As people are attaching more importance to the damp proofing and waterproofing of products, package materials with smaller water vapor permeability becomes the f.3us of package material development and application and is receiving more and more concentrations in recent years.FIELD MANUAL 110 Table 17-1.—A glossary of abbreviations and definitions used in permeability calculations K = Coefficient of permeability in feet (meters) per year under a unit gradient. Q = Steady flow into the well in ft3/sec [m3/sec]. H = The effective head of water in the well in feet (m). For packer tests, determining the effective head is defined

Test Principle:Uses the air flow method or the water vapor transmission method to measure the rate of gas or water vapor passing through the sample. Test Equipment:Depending on the test method, different permeability meters may be needed, such as an air permeability tester for the air flow method, while a humidity control equipment for the .

CO2 transmission rate test by weighing method: Water vapor transmission rate test by inverted cup method: Non-destructive test for packaging seal performance: Multi-station packaging pressure test: Tensile test of packaging materials with ultra-long elongation: Heat-seal strength test for cap films of medical bottles, yogurt cups and jelly cupsspecific goals and customized testing regimes to deal with the multiple numbers of variables within the test procedures. There remains a need for developing test procedures that support conservation aims and enable comparative performance testing of coating materi-als.26 The present work introduces a test procedureLab Asphalt Permeability Testing; Field Permeability Testing of Pavement; Calculating the Coefficient of Permeability; Asphalt permeability has a direct impact on the performance and longevity of pavements. Long-term internal exposure to water and water vapor in the asphalt voids is a significant factor in the premature deterioration of roadways.

water vapour permeability test method

Standard Test Methods for Water Vapor Transmission of Materials E0096-00E01 ASTM . permeance, and permeability are stated in Table 1. All conversions of mm Hg to Pa are made at a temperature of 0°C. 1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user .1.1 This test method covers a procedure for determining the rate of water vapor transmission through flexible barrier materials. The method is applicable to sheets and films up to 3 . 3.1.1 water vapor permeability coeffıcient—the product of the permeance and the thickness of the film. The permeability is meaningful only for homogeneous .

By studying various test methods of water vapor transmission rate, Labthink manufactures many water vapor permeability testers based on ASTM E96/GB 1037 (gravimetric method), ISO 15106-2/ASTM F1249 (infrared sensor method), ISO15106-3 (electrolytic sensor method) and ISO15106-1/ASTME398 (humidity sensor method). Labthink has the most complete .

ASTM E96 Full Name. ASTM E96 – Standard Test Methods for Water Vapor Transmission of Materials. Scope. ASTM E96 outlines standardized test methods to determine the water vapor transmission rate of materials. This property, crucial in construction and packaging industries, quantifies the amount of moisture that permeates a material over a specific area and time. Key Words: water vapor permeability, water vapor transmission rate, cup method, sensor method, desiccant method and water method 1.Overview: . method measure in accordance with test procedures and calculation formula of ASTM E96 should be identical in ideal situation, water method has not been adopted by domestic standards and even current .“water vapor permeability—the time rate of water vapor transmission through unit area of flat material of unit thickness induced by unit vapor pressure difference between two specific surfaces, under specified temperature and humidity conditions. 3.1.1 Discussion—Permeability is a property of a material,

permeability of a body that performs like a material may be used. Permeability is the arithmetic product of permeance and thickness. water vapor permeance Ñthe time rate of water vapor transmission through unit area of ßat material or construction induced by unit vapor pressure difference between two speciÞc Five testing instruments plus a new test apparatus were employed to evaluate the water vapor transport properties of fabrics with low, medium, and high vapor permeability. The test results show that the desiccant inverted cup method generated the highest water vapor transmission rate, followed by the new method, the dynamic moisture permeation .Air permeability is a crucial factor in textile assessment, impacting performance across various industries. This guide offers a comprehensive overview for many of you, including manufacturers, researchers, and consumers. Starting with fundamental concepts and measurement methods, we explore factors influencing air permeability, emphasizing its role in sportswear, filtration, and .

Water Vapor Permeability Test . AIDIMME TECHNOLOGY INSTITUTE Reference: 1506151-01 d Order sheet: 21500534 TEST REPORT n. 221.1.1906.481 .EN.OI AT THE REQUEST OF: . Procedure: free film test Classification of water-vapour transmission rate according to EN 1062-1 Class I hi h Il medium Ill low Materials Laboratory (m)By studying various test methods of water vapor transmission rate, Labthink manufactures many water vapor permeability testing instruments based on ASTM E96/GB 1037 (gravimetric method), ISO 15106-2/ASTM F1249 (infrared sensor method), ISO15106-3 (electrolytic sensor method) and ISO15106-1/ASTME398 (humidity sensor method). Labthink has the .Gravimetric method is the arbitration method of water vapor permeability testing. Data system of sensor method should be calibrated with that of gravimetric method. 1. Water Vapor Permeability of Materials Water vapor permeability of materials is the main index in evaluating water proof property of packing materials such as film and sheets.size 150x150x150 mm, at an age of 28 days. The test cell assembly being used had the provision for testing six cubes at a time. Once the specimens were assembled in the test cells, a water pressure of 500 KPa (5 bar) was applied for 72 hours. Water pressure is applied by means of an arrangement consisting of a water tank connected to an air .

This provides a basis to water vapor permeability testing under special conditions. 2.2 Reference Standard: ASTM E 96 . ASTM E96 is the gravimetric standard with the longest history. It is also the longest-standing standard method for water vapor permeability testing. The first edition was issued in 1953 and has been revised for many times .

water vapor transmission test

Tensile Strength Tester trader

ASTM E96: Water Vapor Transmission test by ASTM E96 is an important test to determine in case of packaging materials und er consideration. This test is used for measuring the transfer of water vapor via semi-permeable and permeable samples. . In calculating the WVTR value, this weight change rate measures the material’s permeability to .

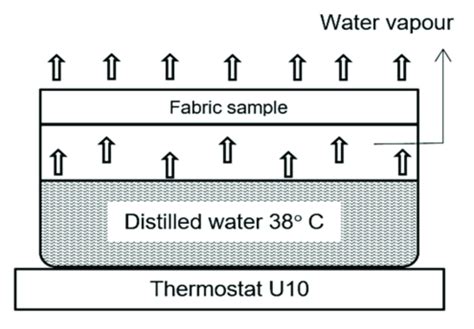

B# Water Upright 73.4℉ (23 ℃) 50% BW# Water Inverted 73.4℉ (23 ℃) 50% C Solid Desiccant Upright 90 ℉ (32.2 ℃) 50% D Water Upright 90 ℉ (32.2 ℃) 50% E Solid Desiccant Upright 100℉ (37.8 ℃) 90% (#)More common procedures adopted in the market WATER VAPOR PERMEABILITY (WVP), BS 7209 PROCEDURE METHOD CUP ORIENTATION .

Tensile Strength Tester sourcing

water vapor transmission rate tester

Resultado da Check freehiteu.com with our free review tool and find out if freehiteu.com is legit and reliable. Need advice? Report scams Check Scamadviser!

water vapor permeability test procedure distributor|water vapor permeance explained